|

Isolators and Containment |

|

|

Laboratory Isolators

- Complete system for the researcher

- Provides maximum operator protection

- Excellent clean ability of the entire interior

- Tailored to typical laboratory process

- Flexible and mobile system

|

|

Back to top of page |

Sterile Isolators

- Provides complete product protection

- Controlled over pressure and integrated LAF systems

- Customised Sterilisation Cycles dependant on application

- Suitable for the execution of sterility tests

|

|

|

Rapid Transfer Port

- Contamination free transfer of objects and product

- Docked to the outside of the isolator

- Employs Double-lid principal

- Approved hazardous material container for transportation by road, sea and air

- Complete flexibility and easy to clean

|

|

|

Continuous Liner Systems

- Allows contamination free outward transfer

- Allows simultaneous packing of objects or products brought out of isolator

- Facilitates safe handling

- Intelligent system enables contamination free exchange of the continuous liner

- No interruption to production

|

|

|

Glove Tester

- Based on pressure drop test

- Checks the integrity of gloves

- Glove ports pneumatically sealed

- Results recorded with a XY plotter

- Mobile & meets the highest FDA & cGMP qualifications

|

|

|

|

Vessels, Skids and Units |

|

|

Single - Layer Pressure Filter/Nutsche Filters

- For the handling of expensive or toxic products

- Automated Central Locking system

- Filters range from 50-300 litres

- Variety of surfaces

- Fitted with choice of manually operated spindle, pneumatic or with hinged open aid

|

|

Back to top of page |

Returnable Stainless Steel Container Systems

- Pressure resistant aseptic containers in sizes 150 to 1,000 litres

- Cubic containers for liquids, viscose media and bulk in sizes 200 to 2,500 litres

- Containers comply with the highest pharmaceutical, biotechnology and food standards

- Available in hermetically welded or standard versions

- Equipped with various heating and individual mixing systems

|

|

|

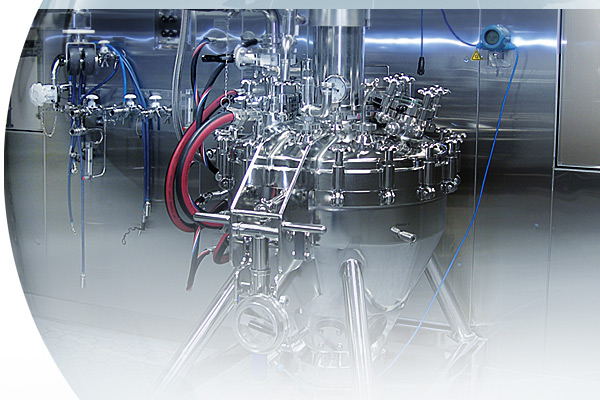

Preparation, Pressure & Reaction Vessels

- Made from stainless and special alloy steels

- Vessel capacity between 5 and 10,000 litres

- Skid range between 5 and 10,000 litres

- CNC grinding technology, plasma arc welding equipment and pickling available

- Subject to extensive quality control tests

|

|

|

|

Drying Technology |

|

|

Mobile Vacuum Contact Dryer

- Enables the process systems to be realized at various places

- Containers ranging from 5 to 350 litres

- Mobile systems due to fixed agitator

- Consistently contamination free product transfer due to split valve docking system

- Easy handling and excellent clean ability

|

|

Back to top of page |

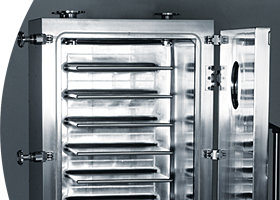

Vacuum Tray Dryer Series VTP

- Suitable for smaller and medium shelves (from laboratory size to 17m²)

- Optimum cleanablility,; carried out manually or by CIP system

- Designed to cGmp and FDA standards

- Integrated internal heating plates

- Complete polished interior

|

|

|

Vacuum Tray Dryer Series VTW

- Designed for high standards in the pharmaceutical industry

- Suitable for medium and large shelves with a standard size of 24m²

- Heating plates welded to the side walls as well as available in a detachable version

- Integrated VTW’s energy inlet and outlet

- Vacuum chambers designed with large radii corners to enhance cleaning and inspection

|

|

|

Vacuum Tray Dryer Series VTC

- Lower cost alternative

- Dryer casings corresponds to the VTW

- Heating plates designed as laser welded pillow plates with smooth and even surfaces

- Heating plates are screwed to the rear panel

- Offers operators interchangability of individual heating panels

|

|

|

Circulating Air Tray Dryer with Filter & Solvent Recovery

- Serves as a universal convective drying system for products containing solvents or water

- Modularly constructed

- Consists of product chamber and separate energy module

- Trays loaded side by side

- Gas tight door

|

|

|